Introduction to Boring Machines

Boring machines, integral to the mining and construction industries, serve a pivotal role in penetrating the earth's surface. These machines are designed for various applications, from tunnel drilling machine operations to the precision work of a line boring machine. The category encompasses a range of equipment, each tailored to meet specific industrial needs, whether it's for large-scale excavation or detailed engineering tasks.

Types and Applications

The spectrum of boring machines includes the robust tunnel boring machine (TBM), essential for creating tunnels for roads, railways, and pipelines. On the other end, the horizontal boring machine is commonly used for creating precise holes in metalwork. The versatility of boring machines extends to specialized equipment like the directional boring machine, which is pivotal for underground utility installations without disturbing the landscape.

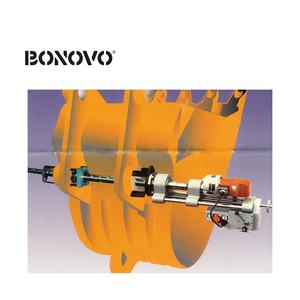

Features and Materials

Boring machines are characterized by their robust construction and the use of durable materials capable of withstanding rigorous drilling tasks. A horizontal borer, for instance, is built with hardened steel components to ensure longevity and consistent performance. The sophistication of a TBM tunnel boring machine includes features that allow it to navigate through varying geological formations, adapting its drilling mechanisms to the hardness of the material being penetrated.

Advantages of Modern Boring Equipment

Modern boring equipment offers significant advantages in terms of efficiency and effectiveness. The automation within a tbm tunnel machine minimizes human error and enhances safety. Similarly, the precision of an in line boring machine ensures exact hole dimensions, crucial for mechanical and structural engineering. These machines are designed to reduce physical strain on operators, enabling extensive operations with less fatigue.

Operational Considerations

The operation of boring machines varies with the type and scale of the project. For instance, the line boring equipment is known for its ability to perform under constrained spaces, delivering high-precision work. In contrast, the expansive nature of a tbm machine requires careful planning and execution, often involving the movement on caterpillar treads to handle inclines up to 25 degrees. Drilling capacities can range significantly, with some machines capable of reaching depths of over 200 meters.

Choosing the Right Boring Machine

Selecting the appropriate boring machine depends on project requirements, including the depth and diameter of the bore, the type of material, and the environment in which the machine will operate. While a borewell machine is ideal for water exploration, a horizontal directional drilling machine might be the choice for installing underground cables. Alibaba.com hosts a diverse array of boring machines to cater to these varied industrial needs, connecting buyers with the equipment that meets their project specifications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4