Understanding Battery Shrink Wrap

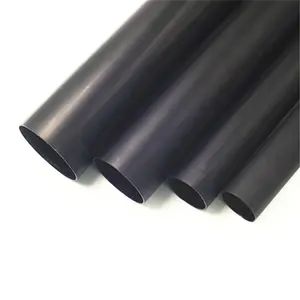

Battery shrink wrap is an essential component in the electrical and electronics industry, serving as a protective layer for battery packs. This material is designed to conform to the battery's shape when heat is applied, ensuring a secure fit. The application of battery heat shrink tubing is not just about aesthetics; it plays a crucial role in insulation and protection from environmental factors.

Types of Battery Shrink Wrap

The market offers various types of battery shrink wrap, each suited to different specifications and uses. Battery pack shrink wrap is commonly used for custom battery assemblies, providing a tailored fit and robust protection. For individual cells, such as the popular 18650 format, 18650 heat shrink is available, which snugly encases the cell, safeguarding against mechanical and electrical stress. 18650 battery heat shrink tubing is another variant, offering a precise fit for this specific battery size, ensuring comprehensive coverage and safety.

Applications and Features

The versatility of battery shrink wrap extends to various applications. In the realm of consumer electronics, heat shrink wrap for battery packs is widely used to maintain the integrity of the power source in devices. For larger applications, such as in electric vehicles, lithium battery pack heat shrink wrap provides a durable shield against the rigors of operation. The material's inherent features, such as resistance to fluctuating temperatures, chemical stability, and electrical insulation, make it an indispensable part of battery safety and longevity.

Material and Advantages

Battery shrink wraps are typically made from polyvinyl chloride (PVC) or polyolefin materials. These materials are chosen for their excellent balance of flexibility, durability, and insulating properties. Battery heat shrink sleeve made from these materials not only protects the battery from external damage but also prevents electrical shorts between cells. Moreover, the use of aa battery shrink wrap and similar products ensures a non-conductive and moisture-resistant barrier, which is vital for the reliable operation of battery packs.

Environmental Resistance

One of the key advantages of using battery shrink wrap is its resistance to environmental hazards. Whether it's a 18650 battery sleeve PVC or a wrap for a full battery pack, these materials are designed to withstand corrosive elements and extreme temperatures. This resilience makes them suitable for use in a wide range of environments, from the controlled conditions of an electronics lab to the demanding surroundings of outdoor equipment.

Choosing the Right Shrink Wrap

Selecting the appropriate battery shrink wrap involves considering the battery size, environmental exposure, and the level of insulation required. Alibaba.com's platform facilitates this selection by connecting buyers with a diverse range of suppliers offering various shrink wrap solutions. Whether you need 18650 shrink wrap or a custom solution for a unique battery pack, the platform provides access to products that meet your specific needs without the constraints of brand loyalty or promotional bias.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4