Battery Manufacturing Plant Overview

The landscape of energy storage and power supply is evolving with the advent of battery manufacturing plants. These facilities are at the forefront of producing batteries that power everything from electric vehicles (EVs) to portable electronics. The rise of electric vehicle battery plants such as those by Ford and Toyota, and the expansion of lithium battery plants, reflect the industry's rapid growth and the increasing demand for sustainable energy solutions.

Types and Applications

Battery manufacturing plants are diverse, ranging from gm battery plants to toyota megasites, each designed to cater to specific types of batteries, such as ultium cells or panasonic ev batteries. These plants serve a critical role in the production of batteries for various applications, including automotive, industrial, and consumer electronics. The versatility of these plants allows them to adapt to different manufacturing requirements, whether it's for a ford ev battery plant or a toyota battery plant.

Features and Materials

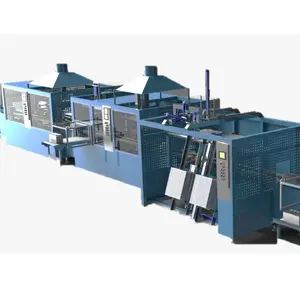

A typical battery manufacturing plant is equipped with advanced machinery capable of handling various materials like lithium, nickel, and cobalt. These plants prioritize precision and efficiency, ensuring that each battery component, from electrodes to electrolytes, meets stringent quality standards. The integration of automation within these facilities, such as in vw battery plants or jlr battery plants, underscores the industry's commitment to innovation and technological advancement.

Advantages of Modern Battery Plants

Modern battery manufacturing setups, including those like the tata lithium ion battery plant, bring numerous advantages. They are designed for scalability and flexibility, allowing for the adjustment of production lines to meet market demands. The focus on sustainability is evident in the operation of lithium factories, which aim to minimize environmental impact while maximizing output. Efficiency is another hallmark of these plants, with many operating with optimized energy consumption to reduce the overall lithium battery manufacturing plant cost.

Environmental and Efficiency Considerations

The shift towards green manufacturing processes is palpable within the sector, with plants like the ford ev plant implementing measures to reduce carbon footprints. The use of renewable energy sources and recycling of materials are steps taken by these plants to promote environmental responsibility. Furthermore, the efficiency of these plants is continually enhanced through technological upgrades, ensuring that the production of batteries, such as those for ev plants, is done with minimal waste and maximum yield.

Conclusion

The battery manufacturing industry is a dynamic field that is critical to the advancement of various sectors, especially in the realm of electric vehicles and renewable energy storage. As the demand for efficient and sustainable batteries grows, so does the importance of sophisticated battery manufacturing plants. These facilities are not just production sites but are also hubs of innovation, driving forward the technologies that will power the future.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4