Understanding Precision Ball Screw Technology

Precision ball screw technology plays a vital role in linear motion systems, ensuring high levels of accuracy and efficiency across various applications. These mechanisms are engineered to convert rotary motion into linear motion, delivering precise and seamless movement for a diverse array of machinery, spanning from aerospace to manufacturing facilities. They are particularly favored in industries like automotive, aerospace, and medicine, where precision and dependability are of utmost importance.

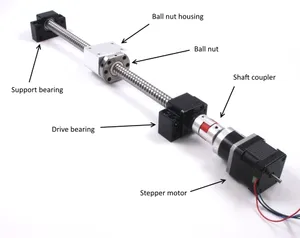

The concept behind precision ball screws is fairly simple. Fundamentally, a precision ball screw comprises a stationary screw and a nut that travels along its threaded shaft. When the screw rotates via an external motor, the nut smoothly moves along the thread without requiring additional guidance. The rolling motion of the ball screw supports the load and minimizes friction, ensuring a precise and fluid linear motion.

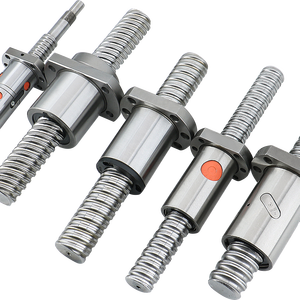

These screws are available in various configurations tailored to specific requirements, each offering distinct levels of precision and operational capabilities. Some are optimized for high-speed functions, while others prioritize high load capacities with minimal backlash. Factors such as material composition, manufacturing techniques, and precision levels collectively influence the performance and suitability of a ball screw for particular tasks.

Varieties of Precision Ball Screw Technology

The range of precision ball screws is extensive, with each type serving distinct needs and applications. Here is an overview of some common variants:

-

Ground Ball Screws: These screws are crafted with exceptional accuracy and find application in scenarios requiring precise positioning, such as semiconductor manufacturing equipment or high-precision machinery.

-

Lead Precision Ball Screws: Designed with a lead tailored for applications prioritizing speed over absolute positioning accuracy.

-

Thrust Ball Screws: Geared towards managing axial loads, commonly utilized in vertical motion systems like lifts and jacks for precise vertical movements.

-

Rolling Ball Screws: Offering enhanced load capacities, frequently employed in industrial machinery for efficient movement of heavy loads.

-

Multiple Start Ball Screws: Featuring multiple threads within a single shaft to expedite motion with less travel, ideal for applications necessitating speed and precision.

Selection of Precision Ball Screw Technology

Choosing the appropriate precision ball screw technology is paramount for optimizing machinery performance and efficiency. When assessing options on Alibaba.com's B2B platform, businesses should consider several factors:

-

Application Requirements: Align the ball screw specifications with your application's demands, factoring in load capacity, speed prerequisites, and environmental variables. Robust designs like rolled thread screws suit high-load applications, whereas ground or milled thread screws are preferable for high-speed machinery.

-

Core Components: Evaluate crucial components such as screw nuts and bearings, as their quality significantly impacts the ball screw assembly's performance and longevity.

-

Material and Manufacturing Process: Opt for materials and manufacturing methods that match durability and precision needs. Materials like stainless steel or hardened alloys offer extended lifespan and reduced maintenance requirements.

-

Customization Capabilities: Seek suppliers providing customization options for non-standard sizes or specific performance attributes your application may require.

Thoroughly considering these aspects concerning your industry's prerequisites, whether in manufacturing plants, construction, or machinery repair establishments, will facilitate an informed decision when procuring precision ball screw technology through Alibaba.com.

Insights on Precision Ball Screw Technology on Alibaba.com

Alibaba.com distinguishes itself as a global marketplace linking businesses with a vast array of precision ball screw suppliers worldwide. Offering a diverse product range tailored to various industrial needs and applications, Alibaba.com streamlines the procurement process for businesses seeking quality linear motion components.

The platform's dedication to fostering international trade is evident through its user-friendly interface supporting local languages and mobile access, enabling buyers to navigate options effortlessly while availing services like order processing and delivery aid. Furthermore, Alibaba.com's Trade Assurance service enhances security by safeguarding payments until confirmed delivery.

By providing an assortment of choices from verified suppliers, Alibaba.com assists businesses in finding suitable precision ball screws without compatibility or quality concerns. This comprehensive approach positions Alibaba.com as an ideal destination for companies aiming to invest in top-tier linear motion solutions enhancing operational efficiency and productivity.

Frequently Asked Questions about Precision Ball Screw Technology

What is precision ball screw technology?

Precision ball screw technology enables highly accurate linear motion by converting rotary motion into linear motion with minimal friction, ensuring smooth operation in various industrial applications.

How does a precision ball screw operate?

A precision ball screw comprises a lead screw, a nut, and ball bearings. As the lead screw rotates, the nut moves along it due to the ball bearings, constrained by the screw's thread pitch.

Which primary industries utilize precision ball screw technology?

Precision ball screw technology finds widespread application in industries like manufacturing plants, machinery repair shops, construction works, CNC machining, and retail sectors requiring precise linear motion.

What materials are typically used in precision ball screws?

Precision ball screws are commonly crafted from materials such as carbon steel, stainless steel, chrome steel, and bearing steel to ensure strength and durability.

How can I select the appropriate precision ball screw for my application?

Consider your application's specific requirements, including load-bearing capacity, speed, required accuracy, environmental conditions, and compatibility with existing systems. The choice between a rolled thread or a ground thread also plays a crucial role.

Can precision ball screws be customized for unique applications?

Yes, precision ball screws can be customized with different materials, lead screw configurations, accuracy grades, and protective features like bellows to suit unique operational and environmental conditions.

What accuracy grades are available for precision ball screws?

Precision ball screws are classified with accuracy grades such as P4, P5, P6, and P7, selected based on the precision level required for the application.

How can I ensure a long service life for my precision ball screw?

Look for ball screws with higher precision ratings (e.g., P4) and made from wear-resistant materials. Regular maintenance checks and adherence to load capacity guidelines will also aid in prolonging service life.

What maintenance practices are necessary for precision ball screws?

Maintenance typically involves regular inspections for wear or damage, lubrication of ball bearings, and ensuring environmental conditions are suitable for the construction materials used.

Are local service locations for precision ball screw technology available on Alibaba.com?

Yes, Alibaba.com facilitates connections with suppliers offering local service locations in countries like the United States, Germany, Turkey, South Korea, Brazil, Canada, India, among others, where you can inquire about customization options.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4