Introduction to Baby Diaper Machines

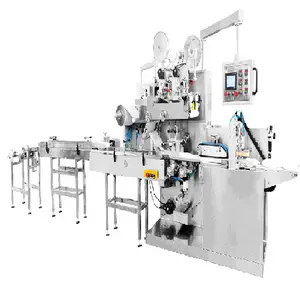

The baby diaper machine is an industrial apparatus designed for the production of baby diapers, an essential product for infant hygiene. These machines are engineered to deliver efficiency, precision, and high output rates, catering to the growing demand for baby care products. With a focus on innovation, baby diaper manufacturing equipment has evolved to meet various market requirements, ensuring consistent product quality and safety.

Types and Applications

There are multiple types of diaper making machines, including semi-automatic and fully automatic versions, each serving different production scales and needs. The applications of these machines span from small-scale production for local brands to high-volume manufacturing for global distribution. They are adept at producing various diaper styles, such as pull-up pants and traditional taped designs, accommodating the diverse preferences of parents and caregivers.

Features and Materials

Modern diaper production lines boast features that enhance the manufacturing process, such as high-speed stable performance and precise weight control systems. The materials used in these machines are typically robust metals and composites that resist wear and tear, ensuring longevity and reliability. Additionally, the integration of smart control systems allows for meticulous management of the production process, from raw material feeding to finished product packaging.

Advantages of Advanced Machinery

The advanced diaper machine technology significantly reduces energy consumption, aligning with eco-friendly production goals. These machines are designed for continuous operation, which minimizes downtime and maximizes productivity. Furthermore, the adaptability of diaper manufacturing machines to different sizes and absorbency levels allows producers to cater to a broad spectrum of market segments.

Innovations in Diaper Machinery

Innovation is at the forefront of diaper machine design, with features like 3D leak prevention, elastic waistbands, and breathable materials being seamlessly integrated into the production process. The latest machines also include quality inspection systems, ensuring that each diaper meets stringent quality standards before it is packaged and shipped.

Choosing the Right Machine

Selecting the appropriate baby diaper manufacturing machine is crucial for businesses aiming to establish or expand their presence in the baby care market. Prospective buyers should consider production capacity, machine flexibility, energy efficiency, and technological sophistication when sourcing equipment. Alibaba.com serves as a platform where you can connect with suppliers to find a machine that aligns with your production needs and goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4