An anodized aluminum sheet is a metal product enhanced by an electrochemical procedure that bolsters its resistance to corrosion and abrasion. This type of sheet is prevalent across numerous industrial domains, prized for its robustness and aesthetic finish. The anodizing technique yields a surface amenable to coloration, offering both practicality and visual appeal.

Types and Characteristics of Anodized Aluminum Sheets

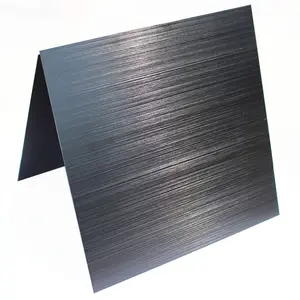

A vast array of anodized aluminum sheets is available on the market, each designed for distinct uses. The black anodized aluminum sheet is preferred in the technology sector for its capacity to absorb light and minimize glare. The clear anodized aluminum sheet is a common sight in architectural contexts, maintaining the metal's luster while enhancing its protection. For sectors focused on aesthetics, such as signage and art installations, the blue anodized aluminum sheet and red anodized aluminum sheet are the materials of choice. In the culinary industry, the non-toxic and heat-resistant features of these sheets are highly valued. The gold anodized aluminum sheets are the luxurious option, frequently employed in upscale electronics or jewelry, providing an opulent look while retaining the intrinsic advantages of the material.

Structure and Operation of Anodized Aluminum Sheets

The anodized aluminum plate is characterized by a thick anodic coating that adheres to the aluminum surface. This coating is an integral part of the metal, ensuring it will not chip or flake away. It is produced via an electrochemical method that transforms the metal surface into a decorative, robust, and corrosion-resistant anodic oxide finish. The anodized layer is non-conductive and its thickness can be adjusted to meet specific requirements. The aluminum beneath remains malleable, allowing for post-anodization bending or shaping without impairing the protective coat.

Materials and Properties

The constituents of anodized aluminum sheet metal are chosen for their compatibility with the anodizing process and their contribution to the end product's characteristics. Aluminum alloys typically include elements like magnesium for added strength and silicon to facilitate casting and machining. The anodizing process itself augments these materials, bolstering their innate resistance to wear and corrosion. The result is a material that withstands environmental challenges while presenting a sleek, professional look.

Business Usages and Applications

Anodized aluminum sheets are employed across a wide spectrum of commercial activities. In the architectural field, they are utilized for building exteriors, window frames, and curtain walls, valued for their structural integrity and visual appeal. The automotive industry leverages anodized aluminum panels for their lightness, aiding in fuel efficiency and vehicular performance. In consumer electronics, these sheets are esteemed for their heat dissipation properties, safeguarding sensitive components in gadgets like smartphones and laptops. Their inert surfaces also make them ideal for food processing and storage equipment, where sanitation is crucial.

Functions of Anodized Aluminum Sheets

The anodized aluminum sheet fulfills a multitude of roles across different sectors. Its non-toxic surface is indispensable for food-related applications, as seen in kitchenware and storage containers. The material's thermal attributes make it suitable for heat exchangers and electronic heat sinks. Moreover, the non-conductive oxide layer is advantageous in electrical insulation, preventing short circuits and other electrical risks.

Features of Anodized Aluminum Sheets

Anodized aluminum sheets boast a plethora of features. They offer extensive customization, with choices in thickness and hues, such as black anodized aluminum sheet metal and gold anodized aluminum sheets. The anodized finish is noted for its dye retention and color stability, essential for branding and product design. Additionally, the anodized layer's integration with the aluminum ensures it will not chip or peel, enhancing the product's longevity and reducing the need for maintenance or repair.

Benefits of Anodized Aluminum Sheets

The advantages of anodized aluminum sheets go beyond their tangible attributes. They offer environmental benefits by being completely recyclable, aligning with eco-friendly business practices. The material's durability reduces the frequency of replacements, translating to cost savings over time. Furthermore, their maintenance is straightforward, requiring only simple cleaning without harsh chemicals, thus preserving the product's appearance for the long haul.

How to Use and Maintain Anodized Aluminum Sheets

To effectively utilize anodized aluminum sheets, one must be cognizant of the environment in which they will be deployed. They should be handled with care during installation to avoid marring the surface. For upkeep, it is advised to clean with water and a gentle detergent, steering clear of abrasive implements that could mar the anodized coating. Regular care will preserve the anodized finish's pristine condition for extended periods.

Choosing the Right Anodized Aluminum Sheet

In selecting the optimal anodized aluminum sheet, considerations such as environmental exposure, mechanical demands, and design preferences must be weighed. Outdoor applications may necessitate a thicker anodized layer for enduring severe weather, whereas indoor uses might be well-served by a thinner coating. Engaging with anodised aluminium sheet suppliers can aid in pinpointing the most suitable option for your project's unique requirements.

Cleaning and Installation Tips

For cleansing, employ a soft cloth or sponge coupled with a gentle detergent to preserve the anodized surface's integrity. During installation, it is imperative to use appropriate tools for any cutting or drilling to prevent damage. It is also vital to select compatible fasteners and sealants to avert galvanic corrosion, a potential issue when different metals come into contact.

Target Audience and Meeting Their Needs

The intended market for anodized aluminum sheets is broad, spanning industries from construction and automotive to electronics and the culinary arts. These sheets satisfy the demands of manufacturers and designers seeking a material that melds resilience with design flexibility. By providing a diverse range of types and finishes, anodized aluminum sheets deliver solutions that are both practical and visually attractive, meeting the precise needs of each sector.

Alibaba.com is a marketplace where businesses can engage with producers offering a wide selection of anodized aluminum sheets, including specialized varieties like anodized aluminum sheets for laser engraving or gold anodized aluminum sheets. Focused on quality and client service, Alibaba.com streamlines the procurement of materials tailored to the diverse requirements of industrial applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4