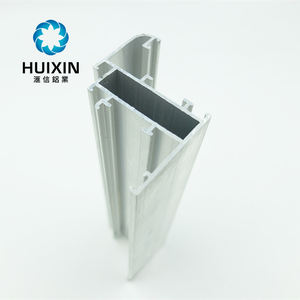

Introduction to Aluminum L Profiles

Aluminum L profiles, commonly known as angle brackets or L-shaped aluminum extrusions, serve as a versatile solution in various industrial, commercial, and construction applications. These profiles are designed to offer a combination of lightweight structure and considerable strength, making them suitable for a broad range of structural and design purposes.

Types and Applications

The applications of aluminum L profiles are diverse, ranging from framing systems and interior design to automotive parts and lighting fixtures. Their unique shape allows for easy assembly and provides inherent structural support, which is essential in construction and manufacturing. In office furniture, these profiles contribute to the aesthetic and functional design, while in engineering, they are integral to plumbing and machinery frameworks.

Features and Materials

Typically made from 6000 series aluminum alloys, aluminum L profiles offer a balance of workability, corrosion resistance, and strength. The temper of these profiles can vary, commonly found within the T3 to T8 range, indicating the level of hardness and strength due to heat treatment and aging. The versatility in their thickness, from 0.2mm to 20mm, allows for customization to meet specific project requirements.

Advantages of Aluminum L Profiles

The advantages of using aluminum L profiles include their adaptability and durability. Aluminum as a material is known for its resistance to corrosion, lightness, and strength-to-weight ratio. These profiles are also non-magnetic and can be recycled, making them an environmentally friendly option. Their ease of machining and finishing means they can be tailored to various specifications, including different shapes such as T-shaped bars, hollow tubes, and solid rounds.

Customization and Variety

Customization is a key aspect of aluminum L profiles, with suppliers offering a range of options in terms of dimensions, colors, and finishes. Whether for aesthetic purposes, such as matching color schemes in design projects, or for functional requirements, like specific angles for load-bearing structures, these profiles can be adapted to suit the needs of the project.

Choosing the Right Profile

Selecting the appropriate aluminum L profile is crucial for the success of any project. Factors to consider include the profile's size, thickness, alloy composition, and temper. It is important to assess the demands of the application to ensure the profile can withstand the environmental conditions and mechanical stresses it will face.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4