Introduction to Acrylic Molding Machines

Acrylic molding machines are integral components in the manufacturing sector, designed for shaping acrylic and other plastic materials into a myriad of products. These machines utilize heat and pressure to mold plastic into desired forms, serving industries ranging from medical to advertising. The versatility of these machines allows for the production of a vast array of items, from intricate components to large-scale sheets.

Types and Applications

The applications of acrylic molding machines are diverse, catering to various sectors such as healthcare, construction, and consumer goods. These machines are adept at producing medical devices, lighting fixtures, and retail displays. Specialized machines are also available for creating detailed signage and artistic installations, demonstrating the adaptability of this equipment to different creative demands.

Features and Materials

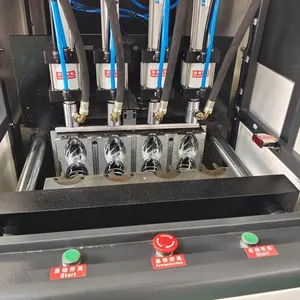

Plastic extrusion machines and vacuum formers are two common types of acrylic molding equipment. Extrusion machines are particularly efficient in creating long, continuous shapes like pipes and sheets, while vacuum formers are suited for making more complex shapes with fine details. The materials used in these machines are typically acrylic pellets or powders, which are known for their clarity, strength, and versatility.

Advantages of Acrylic Molding

The advantages of using an acrylic vacuum forming machine include its ability to produce lightweight, durable products with excellent optical clarity. The process is also relatively quick and can be highly cost-effective for mass production. Additionally, the use of plastic forming machines supports recycling efforts by allowing waste plastic to be reformed into new products, contributing to environmental sustainability.

Innovative Uses and Creative Potential

Beyond traditional uses, acrylic sheet making machines unlock a world of creative potential. They are instrumental in the production of sports equipment, decorative items, and even prototypes for new inventions. The creative limits of plastic molding machines are boundless, with the capability to bring unique designs and innovative ideas to life.

Conclusion

In conclusion, an acrylic molding machine is a versatile and essential tool for businesses looking to shape plastic materials into valuable products. With a range of types and applications, these machines are pivotal in numerous industries, offering the potential for innovation and sustainability in product design and manufacturing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4